Strain sensors can convert mechanical deformation into detectable electrical signals, and have shown good application prospects in the fields of intelligent robots, medical monitoring, human-computer interaction, and bionic prostheses. In particular, real-time monitoring of human motion behavior can effectively assess its health status, which is of great significance in wearable medical diagnosis and personal health monitoring.

For human motion monitoring, an ideal strain sensor device must have both high stretch rate and good stability, so as to provide the possibility of realizing full-scale human motion detection. In addition, due to the diversity and complexity of human motion, the stability of strain sensors under different application conditions (temperature, frequency, etc.) is equally important. However, the currently reported flexible strain sensors often cannot have the above performance at the same time, which limits their application range.

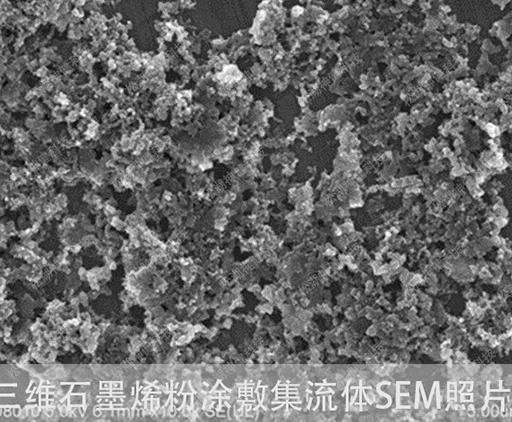

The research group of Professor Xu Ming of Huazhong University of Science and Technology has developed a three-dimensional graphene flexible stretchable strain sensor based on the working principle of "sliding rheostat"; by changing the contact area between adjacent three-dimensional graphene sheets, the resistance changes, the The sensor has a high stretch rate (70%), excellent cycle stability (300,000 times), and maintains a stable response in the frequency range of 0.1-5 Hz and the temperature range of -45 °C-180 °C, achieving full Scale human movement monitoring.

The researchers used three-dimensional graphene as the basic structural unit, synthesized a partially overlapped three-dimensional graphene network by chemical reduction and supplemented by the control of the reduction time, and combined it with an elastic polymer to obtain a flexible stretchable strain sensor . Observation through in-situ transmission electron microscopy revealed that the overlapping three-dimensional graphene sheets produced relative slippage under the action of external force, and their contact area also changed accordingly, resulting in resistance changes.