Songshan Lake Materials Laboratory has developed a new type of mask filter material with better performance than melt blown cloth

In the face of the new crown pneumonia epidemic, the demand for masks at home and abroad has greatly increased. As the core effective filter material for masks, meltblown cloth is in short supply for a while, and the limited production capacity of meltblown cloth has become a major bottleneck in the increase of mask production.

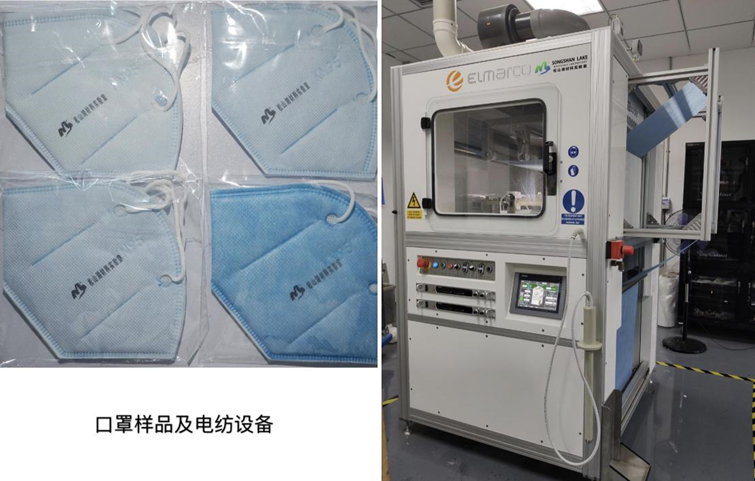

Recently, the reporter learned from the Songshan Lake Materials Laboratory that the laboratory new fiber team led by Professor Yu Jie, based on the nearly 20 years of electrospinning research experience, and the accumulation and technical reserves of the academic direction based on the laboratory layout, carried out " The “electrospun nanofiber membrane used in high-performance protective mask filter membrane” has successfully solved many technical difficulties and prepared nanofiber filter materials that meet the application requirements.

Tested by the third-party authority Guangzhou Inspection, Testing and Certification Group Co., Ltd. (National Certification), the filtration index meets the KN95 mask GB 2626-2006 national standard, which will provide a new solution to the current difficulties encountered in the fight against the epidemic.

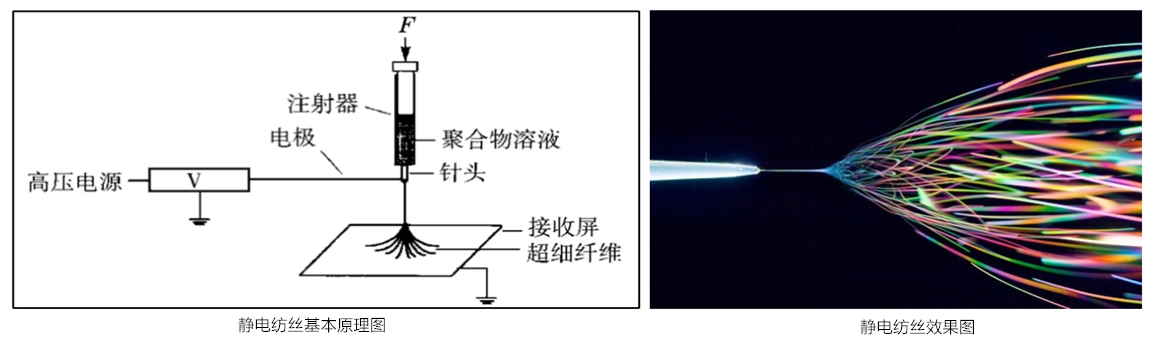

According to the laboratory, nanofiber masks are a new type of mask. Its technical basis is the newly developed electrospinning technology in the past 20 years. The development and popularization of nanofiber masks is not only conducive to solving the problem of insufficient supply of masks, but also has a long-term perspective. Strategic significance.

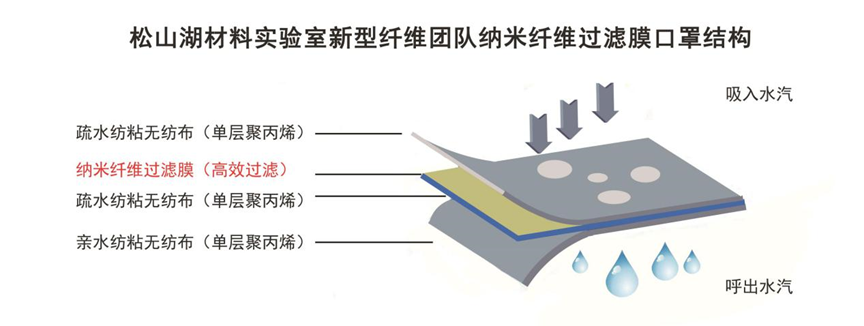

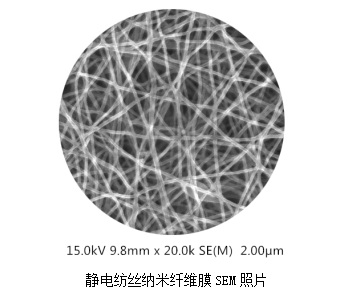

Nano-fiber membranes are used in air filtration. The ultra-high porosity and nano-scale pores give it low-resistance and high-efficiency filtration characteristics, which are better than market melt blown cloth.

At present, the widely used mask filter material is melt blown cloth. The filtration efficiency of melt blown cloth itself is only 30%. It can reach more than 80% after electret treatment. Therefore, melt blown cloth masks are disposable and have Time limitation, washing with water or too long storage time will cause the electric charge to disappear and reduce the filtering effect.

In order to solve the problem of defects such as melt blown cloth, people have turned to nanofiber technology in recent years. In the existing reports, most of the process needs to use organic solvents, which will bring new problems for people to use.

Water-soluble polymers have the advantages of green, health and safety, but have the disadvantage of poor water resistance. The team used its own original process to improve the water resistance of water-soluble polymer fibers and obtained a healthy and environmentally friendly nanofiber filter membrane.

Compared with meltblown cloth, nanofibers have much smaller diameter and pores, no electricity is needed, and its own filtration efficiency can reach more than 95%, so it can be used multiple times and can be stored for a long time.

At the same filtration efficiency, the nanofiber membrane is much thinner than the melt blown cloth membrane, and it is more gentle and comfortable to use. In addition, nanofiber membrane masks have the advantages of high output and low cost, which represent the future development direction.

According to reports, the new fiber team of the Materials Laboratory has deep accumulation in the field of electrospinning nanofibers and has a series of original technologies that can prepare large-area high-strength carbon nanofibers and a variety of functional nanofibers. At present, the team is speeding up the transformation of these technologies into a series of anti-epidemic protective products, including nano-carbon fiber masks, renewable masks, sterilization masks, functional protective clothing, etc.

According to reports, the new fiber team of the Materials Laboratory has deep accumulation in the field of electrospinning nanofibers and has a series of original technologies that can prepare large-area high-strength carbon nanofibers and a variety of functional nanofibers. At present, the team is speeding up the transformation of these technologies into a series of anti-epidemic protective products, including nano-carbon fiber masks, renewable masks, sterilization masks, functional protective clothing, etc.

At the same time, Songshan Lake Materials Laboratory is actively planning to industrialize these technologies, quickly forming production capacity, and contributing to fighting the current epidemic and making long-term strategic reserves.

The Songshan Lake Materials Laboratory has four core sections: public technology platforms and large scientific installations, frontier research sections, innovative model factories, and Guangdong-Hong Kong-Macao Cross-Science Center, and actively builds "frontier basic research → applied basic research → industrial technology research → industrial transformation" The full-chain research model promotes the promotion of hard scientific and technological achievements.

The new fiber team led by Professor Yu Jie is one of the first teams introduced by the laboratory’s innovative model factory. The team is based on its own original technology, oriented to the needs of the country and the economic development of Guangdong Province, with the goal of industrial application, and is committed to continuous electrospinning. Nanofiber preparation and application technology research and development.

[News source] Nanfang Daily

[Reporter] Chen Qiliang

[Source] Songshan Lake Material Laboratory