The cost of carbon fiber materials is the first to bear the brunt. Compared with traditional metal materials, the cost of carbon filaments and resin materials used in carbon fiber products are higher. The production of nanofiber membranes requires high-temperature carbonization and graphitization.

consumes a lot of energy, and the production process is complicated, difficult, and the cost of manpower and material resources is also high. This increases the cost of materials.

Carbon fiber products are a kind of commodity. The products are mainly affected by market supply and demand. The production of raw material carbon fiber is mainly controlled by the United States and Japan, which is basically a monopoly. Therefore, if you want to produce high-performance carbon fiber products, raw materials should rely on imports. And with strict control, it also increases the cost of carbon fiber products.

Light weight and high strength: The well-known advantages of carbon fiber materials are light weight and high strength. The density of carbon fiber materials is only 1.7g/m3, which is 60% of aluminum alloy and less than 1/4 of steel. There are many applications in weight-reducing components. At the same time, the mechanical properties of carbon fiber materials are outstanding, and their tensile strength is several times that of steel. The comprehensive indicators of specific strength and specific modulus are better than existing structural materials, and they also have outstanding The flexural strength and shear strength of this product can effectively meet the needs of use.

Chemical properties: The big difference between carbon fiber and metal materials is that carbon fiber is a non-metal material, so carbon fiber materials have low electrochemical activity, outstanding corrosion resistance and aging resistance, and can adapt to a variety of working environments and extend carbon fiber products. Life.

Thermal performance: The production of carbon fiber requires high-temperature carbonization and graphitization. The required temperature is very high, so the working temperature of carbon fiber itself is very high, but carbon fiber requires resin to form carbon

-Dimensional composite materials are used, so the general working temperature of carbon fiber composite materials is 150°C, while the current working temperature of thermoplastic carbon fiber materials can reach higher. Thermal expansion coefficient of carbon fiber material

basically will not deform with the change of working temperature, to ensure the stability of the size.

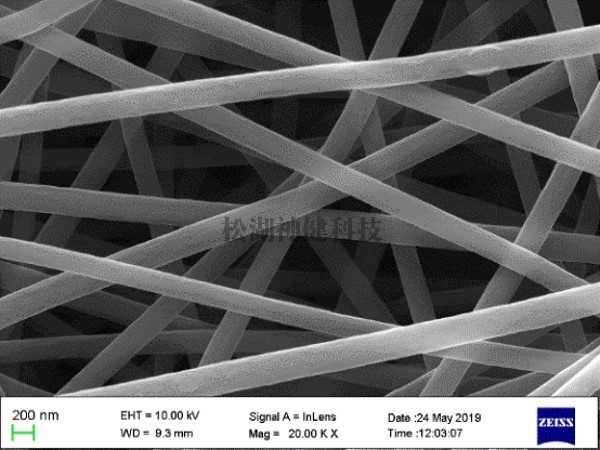

Songhu Shenjian Technology (Dongguan) Co., Ltd. relies on the Songshan Lake Materials Laboratory, developed by the laboratory's new fiber team. The company is engaged in the research and development, production, sales, promotion and service of new material technology and its products. The main products include a series of new materials such as nano-carbon fiber, three-dimensional graphene powder, electrospun polymer nanofiber membrane, and electrostatic spinning series equipment. Accept customization, the company's technology is the team's independent original. The company's products are widely used in energy, environmental protection, chemistry and chemical engineering, health protection, scientific research and other fields. The company adheres to the concepts of innovation, service and integrity, is committed to the research and development of new materials and technologies, and provides the society with high-quality products and innovative technologies.