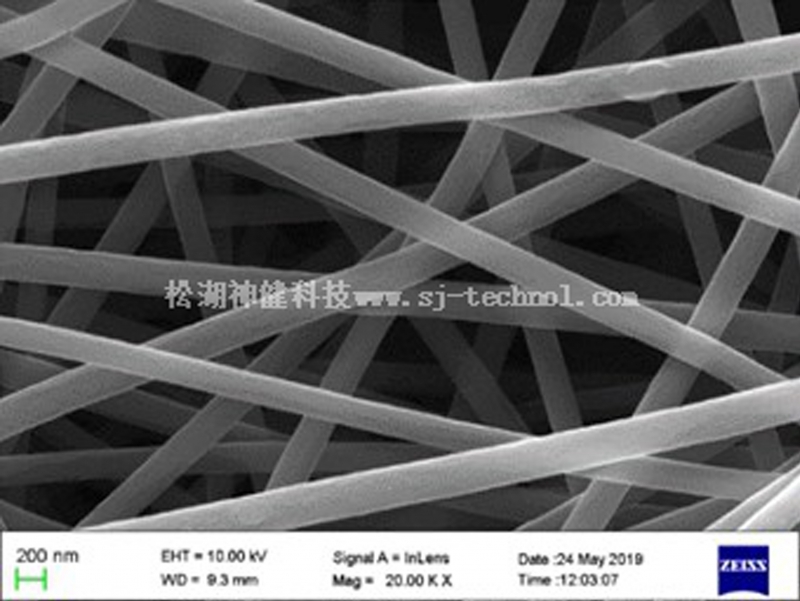

Carbon nanofiber refers to a fibrous nano-carbon material formed by crimping multiple graphite sheets. Its diameter is generally 10~500nm, and its length is distributed in 0.5~100μm. It is a one-dimensional carbon between carbon nanotubes and ordinary carbon fibers. material.

Scientists have gradually discovered that carbon materials are superior to other materials in terms of hardness, optical properties, heat and radiation resistance, chemical resistance, electrical insulation, conductivity, and surface and interface properties. It can be said that carbon materials almost include the earth. The characteristics of all the above substances, such as hard-soft, insulator-semiconductor-good conductor, insulation-good heat conduction, full light absorption-full light transmission, etc., have a wide range of uses. The research on carbon nanotechnology is quite active and diverse Nano-carbon crystals, needles, rods, barrels, etc. emerge in endlessly. According to theoretical calculations, containing 20 carbon atoms is only made up of regular pentagons, and C60 molecules are the smaller one of the fullerene structure molecules. Considering the angle and strength of the original intermination, people have always It is believed that such molecules are very unstable and difficult to exist. German and American scientists have produced C60 cage molecules to solve an important research topic in the field of materials science. Among the carbon nanomaterials, new carbon materials such as carbon nanofibers and carbon nanotubes have many excellent physical and chemical properties and are widely used in many fields.

Nano carbon fiber also has the excellent physical, chemical and mechanical properties of carbon fiber, and it is expected to realize the integrated preparation of material preparation-structure/functional components. Carbon nanofibers are mainly synthesized by chemical vapor deposition or electrostatic spinning. Carbon nanofibers synthesized by chemical vapor deposition method have problems such as difficult to control the uniformity of the tube diameter, the removal of the catalyst will destroy the fiber structure, and the process scalability is not good. The electrospinning technology can achieve high-energy control of fiber diameter and length by adjusting technical parameters such as electric field strength, spinning distance, nozzle size, spinning dope concentration, and solvent volatility. It can also achieve high-energy control of fiber diameter and length by adjusting carbonization temperature. Adjustment of physical, mechanical and chemical properties, graphitization degree, etc. The important development direction of the electrospinning technology to synthesize carbon nanofibers is: how to effectively realize the spinning of full-scale macrostructures, that is, using electrospinning technology to synthesize the original silk layer of the structure/functional part in one step, and obtain carbon nanofibers Structural/functional components of the ply.

Songhu Shenjian Technology (Dongguan) Co., Ltd. relies on the Songshan Lake Materials Laboratory, developed by the laboratory's new fiber team. The company is engaged in the research and development, production, sales, promotion and service of new material technology and its products. The main products include a series of new materials such as nano-carbon fiber, three-dimensional graphene powder, electrospun polymer nanofiber membrane, and electrostatic spinning series equipment. Accept customization, the company's technology is the team's independent original. The company's products are widely used in energy, environmental protection, chemistry and chemical engineering, health protection, scientific research and other fields. The company adheres to the concept of innovation, service, and integrity, is committed to the research and development of new materials and technologies, and provides the society with high-quality products and innovative technologies.