The advancement of nanotechnology has aroused people's interest in the development of nanocellulose-based virus removal filters, mainly focusing on adsorption filters through electrostatic interaction rather than size exclusion. The filter membrane is prepared by compounding nano-cellulose with other synthetic materials, because pure nano-cellulose will be keratinized after wetting and drying, forming a dense, non-porous lump. However, there are also attempts to use 100% natural, unmodified cellulose nanofibers as a filter membrane based on size exclusion.

Nanofibers are new materials obtained after chemical treatments such as oxidation or hydrolysis of cellulose materials. In addition to the hydroxyl groups of the cellulose itself, nanofibers also have hydrophilic functional groups such as carboxyl groups, aldehyde groups, and sulfonic acid groups generated by the oxidation process. , The existence of these functional groups heralds its broad application fields.

Nanofiber membrane, as a new type of nanomaterial, is also incorporated into nanofiltration membranes and reverse osmosis membranes to improve the efficiency of salt water and seawater desalination. Nanofiltration membranes are mainly used in the pretreatment process of hard water softening and desalination, as well as some fine separation industries.

The production of a small mask is traceable along the supply chain, and requires upstream and downstream industrial chain support including non-woven fabrics, meltblown fabrics, polypropylene, meltblown equipment, and packaging machines. Failure to keep up with any link will affect the mass production of masks. The demand for nanofiltration membranes with high throughput and high separation selectivity is increasing. Generally speaking, increasing the flux of nanofiltration membranes often results in a drop in membrane rejection.

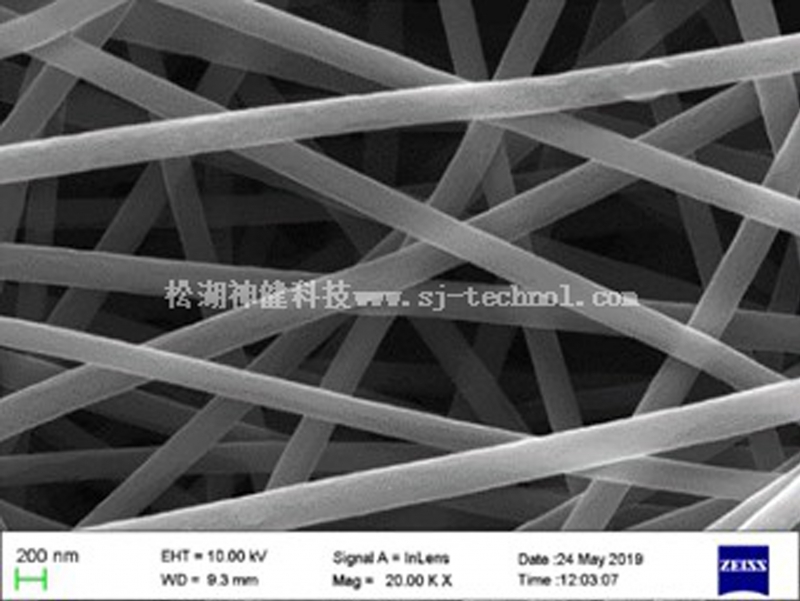

The electrospun nano carbon fiber membrane is prepared by pre-oxidation, carbonization, and graphitization treatments using electrospun polyacrylonitrile fiber as the precursor. The diameter is 100-200nm, which is more than 20 times smaller than conventional carbon fiber diameter and more than 20 times the specific surface area. , The cross-sectional area is reduced by more than 400 times, resulting in a series of superior performances, which have a wide range of application values. Application areas include high-strength composite materials, conductive composite materials, electromagnetic shielding, electrochemical electrodes, catalyst carriers, separation filters, heating elements , Fuel cell gas diffusion layer, etc.

Songhu Shenjian Technology (Dongguan) Co., Ltd. relies on the Songshan Lake Materials Laboratory, developed by the laboratory's new fiber team. The company is engaged in the research and development, production, sales, promotion and service of new material technology and its products. The main products include a series of new materials such as nano-carbon fiber, three-dimensional graphene powder, electrospun polymer nanofiber membrane, and electrostatic spinning series equipment. Accept customization, the company's technology is the team's independent original. The company's products are widely used in energy, environmental protection, chemistry and chemical engineering, health protection, scientific research and other fields. The company adheres to the concept of innovation, service, and integrity, is committed to the research and development of new materials and technologies, and provides the society with high-quality products and innovative technologies.