Nanofiber filter membranes can be roughly divided into cellulose nanonets, cellulose nanocrystals and cellulose nanofibers according to their length and diameter.

Nanofiber membrane can be stably dispersed in aqueous solution or other polar organic solvents (except cellulose nanomesh), so it is easy to process and apply, and it has good composite properties with other materials.

Nanofiber membranes are widely used in the field of microfiltration, mainly for the filtration of microparticles, the adsorption of bacteria, viruses, and heavy metal ions in drinking water, and the purification of wastewater from printing and dyeing wastewater. Because nano cellulose is dispersed in water in a suspended state, nano cellulose can be used as an adsorbent alone or combined with a certain carrier to prepare a film-forming material.

With the acceleration of industrialization, environmental destruction and pollution have intensified, causing severe haze weather in large cities in developing countries. The tiny particles (such as PM2.5) and even nanoparticles in the air will enter the lungs with breathing and accumulate in the respiratory system, causing serious damage to the respiratory system.

In view of this situation, from the perspective of solving the problem, it is necessary to eliminate the source of pollution, that is, to reduce the emission of harmful gases or smoke, or to filter the discharged smoke to obtain clean air before being discharged into the atmosphere; from the perspective of personal protection In general, it is necessary to produce filter membrane materials such as filter masks that can effectively filter PM2.5 and smaller particles to reduce the inhalation of harmful gases and particulates. Therefore, the development of high-energy and cheap air filtration membranes once became the focus of attention of researchers and businesses.

Nano fiber filter membrane can block small water droplets (drizzle) from the outside, and only allow water vapor molecules to pass through. This is the material characteristics required for outdoor sportswear and special protective clothing. It has the characteristics of high filtration efficiency and low filtration resistance, and has selective filtration, such as tap water filtration, which can filter all the harmful components of the body in the tap water, while retaining the trace elements and minerals that are beneficial to the body;

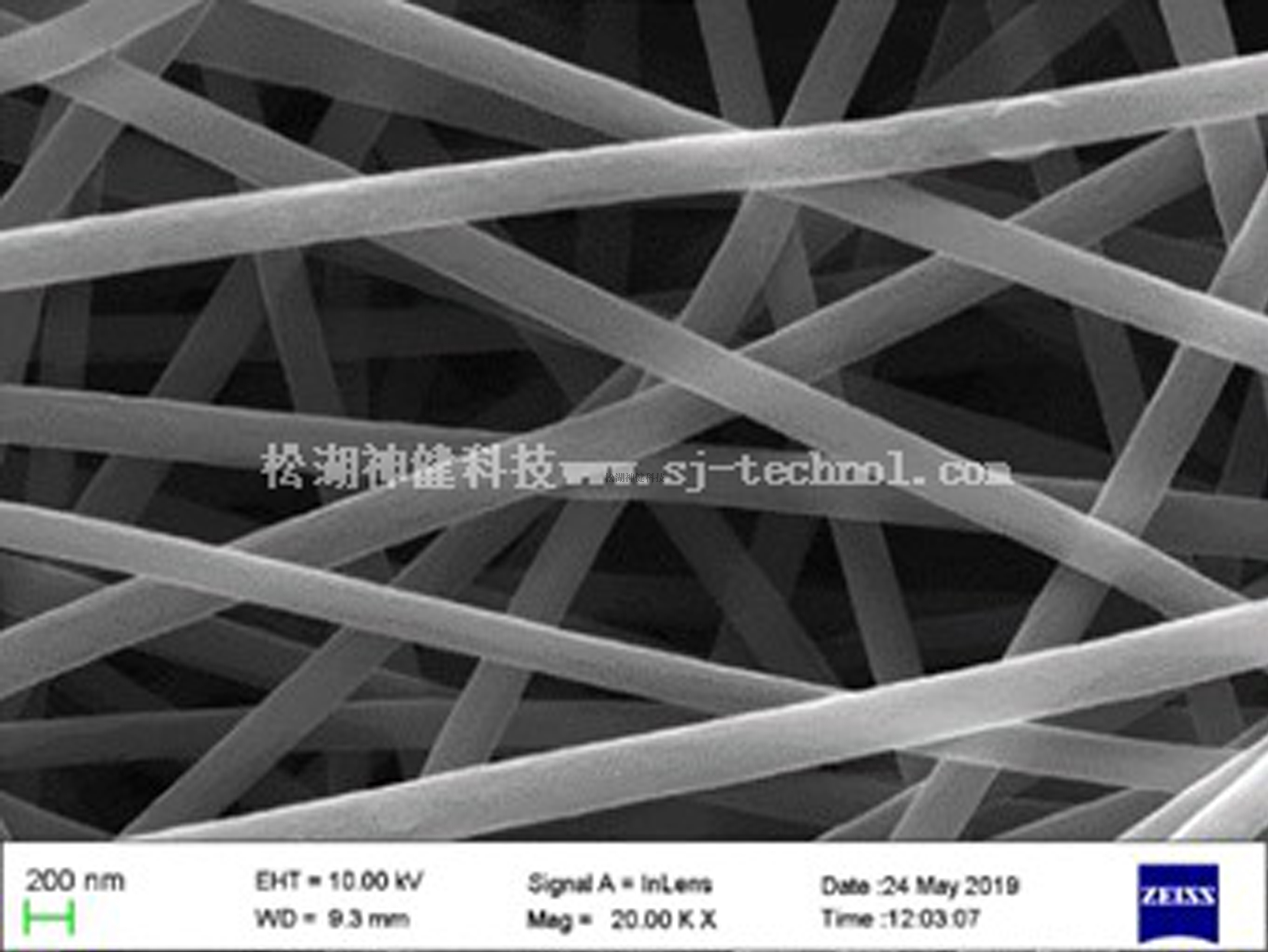

Nano carbon fiber membranes are prepared by pre-oxidation, carbonization, and graphitization treatments using electrospun polyacrylonitrile fiber as the precursor. The diameter is 100-200nm, which is more than 20 times smaller than conventional carbon fiber diameter, and its specific surface area is increased by more than 20 times. The area is reduced by more than 400 times, resulting in a series of superior performances, which have a wide range of application values. The application fields include high-strength composite materials, conductive composite materials, electromagnetic shielding, electrochemical electrodes, catalyst carriers, separation and filtration, heating elements, fuels Battery gas diffusion layer, etc.