The current methods for preparing porous nano-carbon fibers mainly include activation method and template method. The activation method is mainly to etch carbon nanofibers with corrosive chemical reagents such as KOH or HNO3 to make pores, and the template method is mainly to form porous carbon fibers in situ by calcining a mixture of pitch or polyacrylonitrile and a pore former. However, the activation method is usually more complicated and has pollution and safety issues, while the template method requires a large amount of organic solvents. In addition, the carbon nanofibers prepared by these two methods have low porosity and conductivity. On the one hand, in order to ensure the integrity of the carbon nanofiber membrane structure, most of the reported porous carbon nanofibers have a porosity of less than 20%; on the other hand, the conductivity of these porous carbon nanofibers is usually less than 10 s/cm. Therefore, how to improve the porosity and conductivity of the porous carbon nanofiber membrane while maintaining its integrity is a challenge.

The current annual demand for carbon nanofibers is only about 110 tons, and the price is about $220 per kilogram. Mainly used for static dissipation of automobile fuel tanks, semiconductor production, and electromagnetic shielding of electronic products. There are also large markets in the fields of lithium batteries, super-capacity capacitors, and combustion batteries. For structural parts, nano-carbon fiber is currently not used as a main reinforcement material, but as an additive to improve the mechanical, electrical, and thermal conductivity of the matrix material, so as to improve the interlayer shear strength, improve the thermal expansion coefficient, electrical conductivity and thermal conductivity. .

In the next 5-10 years, the market for carbon nanofibers will develop greatly. Large-scale production lines will appear, and the price will drop to about 44 US dollars per kilogram. When the price of nano-carbon fiber drops to about 11 US dollars per kilogram, the market for structural applications will rapidly expand. As a nano-scale reinforced material composite technology also needs to be improved. By then, the market for nano-carbon fiber will expand to more than 45,000 tons.

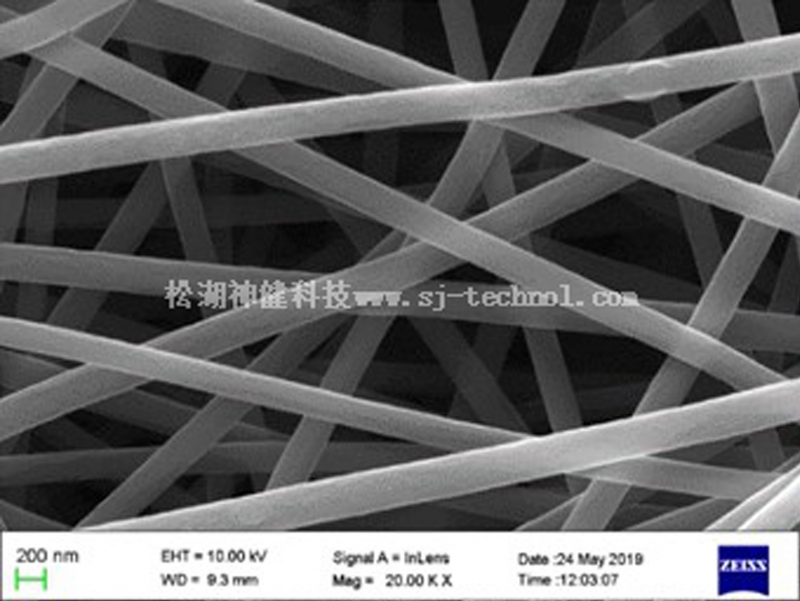

Nano carbon fiber is mainly synthesized by chemical vapor deposition method or electrostatic spinning method. Carbon nanofibers synthesized by chemical vapor deposition method have problems such as difficult to control the uniformity of the tube diameter, the removal of the catalyst will destroy the fiber structure, and the process scalability is not good. The electrospinning technology can achieve high-energy control of fiber diameter and length by adjusting technical parameters such as electric field strength, spinning distance, nozzle size, spinning dope concentration, and solvent volatility. It can also achieve high-energy control of fiber diameter and length by adjusting carbonization temperature. Adjustment of physical, mechanical and chemical properties, graphitization degree, etc. The important development direction of the electrospinning technology to synthesize carbon nanofibers is: how to effectively realize the spinning of full-scale macrostructures, that is, using electrospinning technology to synthesize the original silk layer of the structure/functional part in one step, and obtain carbon nanofibers Structural/functional components of the ply.

Songhu Shenjian Technology (Dongguan) Co., Ltd. relies on the Songshan Lake Materials Laboratory, developed by the laboratory's new fiber team. The company is engaged in the research and development, production, sales, promotion and service of new material technology and its products. The main products include a series of new materials such as nano-carbon fiber, three-dimensional graphene powder, electrospun polymer nanofiber membrane, and electrostatic spinning series equipment. Accept customization, the company's technology is the team's independent original. The company's products are widely used in energy, environmental protection, chemistry and chemical engineering, health protection, scientific research and other fields. The company adheres to the concept of innovation, service, and integrity, is committed to the research and development of new materials and technologies, and provides the society with high-quality products and innovative technologies.