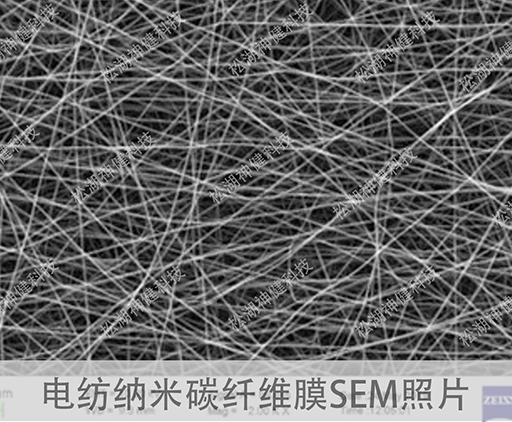

Knitted structures are increasingly used in high modulus fiber-reinforced composite materials due to their good elasticity, energy absorption, drape and formability, and nanofiber membranes are one of the applications. However, due to the high strength and high modulus characteristics of high modulus fibers and the particularity of the knitting structure of the knitting process, it is very difficult for high modulus yarns to successfully complete the knitting loops. Let me share with you the influence on the knitting performance of the nanofiber filter membrane. the elements of.

We analyze only from the performance of the yarn itself, the nanofiber filter membrane has a large elastic modulus and friction coefficient and is a brittle material. The surface of the nanofiber filter membrane yarn is relatively rough and bends easily, so the nanofiber filter membrane is woven knitted fabric The difficulty is greater.

1. The friction coefficient of the nanofiber filter membrane yarn is 0.45. This large friction coefficient causes the cloth surface to rise with the pointer when the knitting needle rises along the triangle, which will cause the old loop to fail to unwind and make the knitting impossible. Go smoothly. In addition, the yarn has a large friction coefficient, which is easy to wear the knitting machine parts.

2. The complete performance of the nanofiber filter membrane yarn is poor, which makes the amount of yarn transferred from the input yarn and adjacent coils of the new coil during the unwinding stage is relatively small, so the coil formed by the nanofiber filter membrane is smaller than the real ugly one. Easy to break.

3. The high modulus of the nanofiber filter membrane combined with its own brittleness can make the nanofiber filter membrane susceptible to bending stress during the weaving process, and even small deformation will cause breakage.