Criteria and test methods for evaluating the quality of carbon nanofibers:

Physical property test

Tensile test: According to the standard such as GB/T 3362-2017, the use of electronic testing machine to tensile test nanocarbon fiber, can obtain its tensile strength, elastic modulus and elongation at break and other key indicators. Tensile strength reflects the ability of nanocarbon fiber to resist tensile failure, elastic modulus reflects its stiffness in the elastic range, and elongation at break indicates its deformation degree at fracture.

Fiber diameter measurement:

Microscopy: The nanocarbon fiber sample is placed under an optical microscope, amplified through the eyepiece and objective lens, and the fiber diameter is measured using a vernier caliper or a microscope eyepiece dial. The method is simple and low cost, but the accuracy is limited, and it is suitable for measuring fibers of more than 10 microns.

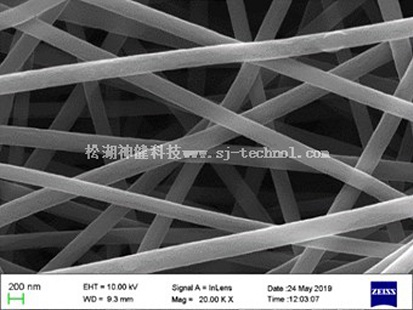

Scanning electron microscopy: The scanning electron microscope is used to observe the surface morphology and structure of the sample, and the image data is processed by the computer to accurately measure the fiber diameter. Its high accuracy can measure fibers of several nanometers, but the equipment is expensive and difficult to operate.

Raman spectroscopy: by irradiating the surface of the sample, measuring the reflection or scattering spectrum, analyzing the vibration state of the carbon fiber molecules, and then calculating the fiber diameter. This method is a non-contact measurement, without sample processing, can achieve online measurement, but requires a high-precision spectrometer, and the measurement time is long.

Density determination: According to the method of GB/T 30019-2013, the density gradient method and liquid displacement method can be used to measure the density of nanocarbon fiber. Density is one of the important factors affecting its mechanical properties and applications, which is of great significance for evaluating the quality and properties of materials.

Specific surface area test: The common method is nitrogen adsorption method, by measuring the adsorption amount of carbon nanofibers to nitrogen at low temperature, according to BET theory to calculate its specific surface area. The size of specific surface area is closely related to the adsorption properties and chemical reactivity of carbon nanofibers, which is one of the important indexes to measure their quality.

Porosity measurement: mercury injection method, gas adsorption method can be used to measure the porosity of carbon nanofibers. The size of the porosity will affect the mechanical properties of the material, permeability, etc. For some specific applications, such as the preparation of composite materials, adsorption separation, etc., it is necessary to control the appropriate porosity.

Nanocarbon fiber

Chemical property test

Chemical composition analysis:

Infrared spectrum analysis: The absorption spectrum of carbon nanofibers in the infrared region is measured by infrared spectrometer, and its chemical composition and functional group structure are determined by analyzing the characteristic absorption peak in the spectrum.

X-ray diffraction analysis: The diffraction pattern of carbon nanofibers is measured by X-ray diffractometer, and its crystal structure and phase composition are analyzed according to the position and intensity of diffraction peaks.

Elemental analysis: The use of elemental analyzer and other equipment to determine the content of carbon, hydrogen, oxygen, nitrogen and other elements in carbon nanofibers to assess their purity and chemical composition.

Thermal stability test: According to the method of GB/T 31959-2015, the thermogravimetric analyzer is used to perform thermogravimetric analysis of carbon nanofibers to measure their mass loss at different temperatures, so as to evaluate their thermal stability. Thermal stability is important for the application of carbon nanofibers in high temperature environment.

Surface chemical properties test: Through X-ray photoelectron spectrometer, contact Angle measuring instrument and other equipment, the surface element composition, surface energy, surface charge and other surface chemical properties of nanocarbon fiber are measured. These properties will affect the interaction of carbon nanofibers with other substances, such as interface bonding properties in composite materials.

Electrical performance test

Resistivity measurement: According to the method of GB/T 32993-2016, the volume resistivity or surface resistivity of nanocarbon fiber is measured by a resistivity tester. Resistivity is an important index to measure the electrical conductivity of carbon nanofibers, which has a key influence on their applications in electronics, energy and other fields.

Electrochemical performance test: electrochemical testing methods such as cyclic voltammetry and constant current charge-discharge method were used to study the electrochemical behavior of nanocarbon fiber in electrolyte solution, such as capacitance and lithium ion storage performance. These tests are important for evaluating the performance of carbon nanofibers in energy storage applications such as supercapacitors and lithium-ion batteries.

Microstructure characterization

Scanning electron microscope observation: Scanning electron microscope was used to observe the surface morphology, diameter distribution, fiber interaction and other microstructure characteristics of carbon nanofibers. By analyzing the microstructure, we can understand the growth mechanism, defects and effects on the properties of carbon nanofibers.

Transmission electron microscopy observation: Transmission electron microscopy can obtain finer microstructure information of carbon nanofibers, such as internal crystal structure, lattice fringes, etc., which is helpful for in-depth study of its physical and chemical properties.