The preparation process of carbon nanofibers mainly includes chemical vapor deposition, electrospinning, etc. The key steps and technical difficulties of these methods are as follows:

Chemical vapor deposition

Key steps:

Catalyst preparation: Selecting suitable transition metals (such as Fe, Co, Ni and their alloys) to make ultrafine particles as catalysts is one of the key factors for the growth of nanocarbon fibers, and the activity and particle size of the catalyst will directly affect the growth rate, diameter and quality of carbon fibers.

Carbon source selection: Commonly used carbon sources are hydrocarbons, such as methane, ethylene, acetylene and so on. The type and concentration of carbon source will affect the growth rate and structural properties of carbon nanofibers.

Reaction temperature control: the reaction is generally carried out at a high temperature of 600℃ ~ 1200℃, and the reaction temperature is an important parameter affecting the growth of carbon nanofibers. Different temperatures will lead to differences in the crystallinity, diameter, length and other properties of carbon fibers, which need to be accurately controlled.

Gas flow regulation: As a carrier gas, the flow rate of hydrogen will affect the atmosphere of the reaction system and the decomposition rate of carbon sources, and then affect the growth of carbon nanofibers. It is necessary to adjust the flow ratio of hydrogen and carbon sources reasonably.

Technical difficulties:

Homogeneous dispersion of catalyst: to make the catalyst evenly dispersed in the reaction system, otherwise it will lead to uneven growth of carbon nanofibers accurate control: small changes in reaction conditions such as high temperature and gas flow may have a greater impact on the structure and performance of carbon nanofibers, requiring high-precision equipment and strict process control to ensure the stability of reaction conditions.

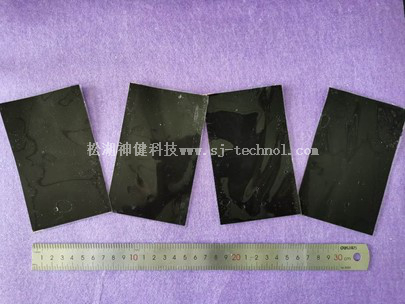

Nanocarbon fiber

Purification of products: The nanocarbon fiber generated by the reaction may be attached to some impurities, such as unreacted catalyst particles, by-products of carbon source decomposition, etc., requiring complex post-treatment processes to purify products to meet the requirements of different application fields.

Electrospinning

Key steps:

Spinning solution preparation: Dissolve the polymer (such as polyacrylonitrile, polyvinyl alcohol, etc.) in the appropriate solvent, and add carbon nanotubes, metal oxides and other additives as needed to form a uniform and stable spinning solution, the type and concentration of the polymer and the type and content of the additives will affect the nature of the spinning solution and the performance of nanocarbon fiber.

Electrospinning parameter setting: including the applied voltage, the distance between the spinneret and the collector, the flow rate of the spinning solution, etc., these parameters directly determine the diameter, morphology and orientation of the nanofibers, and need to be determined by a large number of experimental optimization parameter combinations.

Pre-oxidation treatment: The polymer nanofibers obtained by electrospinning are pre-oxidized in the air to make the polymer molecular chain cross-linked and cyclization reaction, and improve the thermal stability of the fibers. Factors such as pre-oxidation temperature, heating rate and holding time have important effects on the pre-oxidation effect.

Carbonization process: The pre-oxidized fiber is carbonized at high temperature under an inert atmosphere to convert the polymer into a carboniferous material and form a nanocarbon fiber. The choice of carbonization temperature, heating rate and holding time will affect the properties of the nanocarbon fiber such as crystallinity, specific surface area and pore size distribution.

Technical difficulties:

Stability and spinnability of the spinning solution: the spinning solution formulated needs to be stable for a long time and has good spinnability, otherwise it is prone to gelation, blocking the nozzle or spinning interruption, affecting the production efficiency and product quality.

Fiber diameter and shape control: In order to accurately control the diameter and shape of nanofibers to meet the needs of different application scenarios, it is necessary to fine-adjust the parameters of electrospinning, and also consider the influence of environmental factors on the spinning process, such as temperature and humidity.

Fiber structure maintenance during the pre-oxidation and carbonization process: during the pre-oxidation and carbonization process, the fiber is prone to shrinkage, deformation and even fracture, resulting in a decline in the mechanical properties of carbon nanofibers. It is necessary to optimize the pre-oxidation and carbonization process and take appropriate measures to maintain the structural integrity of the fiber, such as controlling the heating rate and adding appropriate additives.